From raw fibers to spun yarn and thread, both natural and synthetic, the journey of these delicate textiles from their source to the end consumer is fraught with challenges. Peninsula Plastics is proud to offer innovative solutions for the textile industry’s packaging challenges by manufacturing customized lids, pallets, and separators that protect textiles during transit.

The Delicate Nature of Textiles

Textiles, whether natural or synthetic, possess delicate properties that require careful handling throughout the supply chain. Fabrics can be prone to damage temperature variations, dust, and rough handling. The integrity of fibers, yarns, and threads can be compromised if exposed to unfavorable conditions during transit. It is, therefore, imperative for textile companies to prioritize the protection of these materials to ensure the quality and durability of their products.

Customized Packaging for the Textile Industry

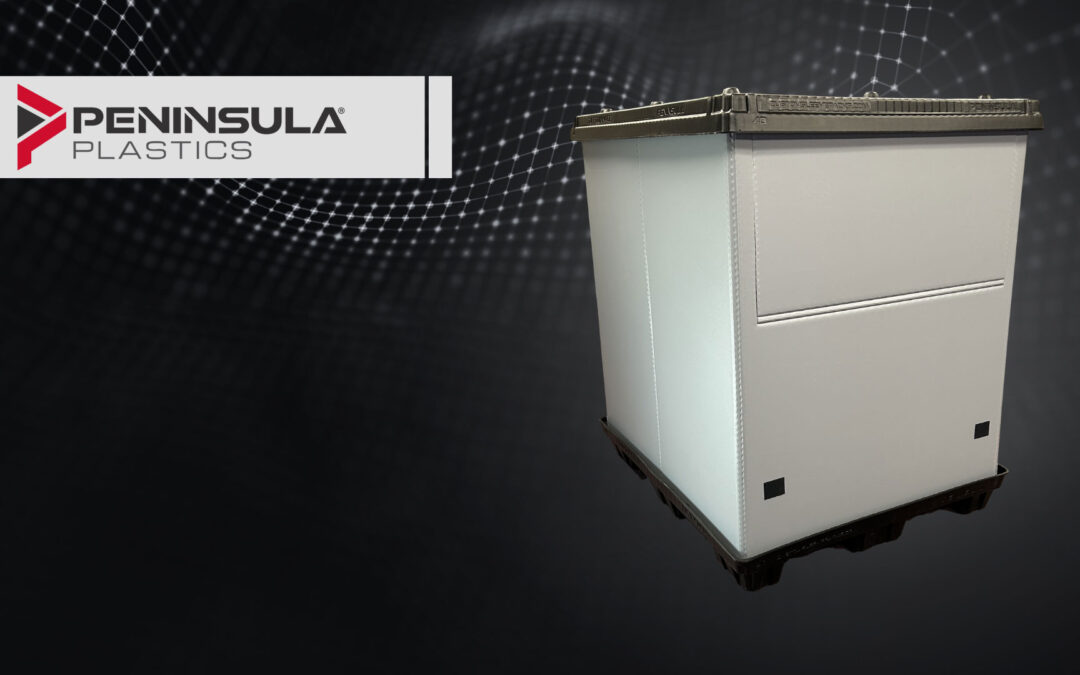

Peninsula Plastics has led the way for the innovation of yarn packs, comprised of a custom three-part HDPE [High-Density Polyethylene] system: a top cap/lid, separators to allow for layering, and a base/pallet. By recognizing the unique requirements of the textile industry, Peninsula Plastics has developed customized and standardized solutions to address its needs. Being a forward-thinking company has aided in revolutionizing the way textiles are transported to enhance overall efficiency. Being able to reuse lids, separators and pallets offers a cost-effective solution for clients to save money when utilizing full loop routing.

Lid / Top Cap

The Lid is an indispensable part of the textile yarn pack. Designed to provide a secure environment that protects textiles from external elements during transit and holds all the pieces together. Lids provide stability to allow yarn packs to stack as tall as three packs high safety on trucks and even higher within warehouse ceiling limitations. These advancements ensure that fibers, yarns, and threads arrive at their destination in pristine condition, free from any damage.

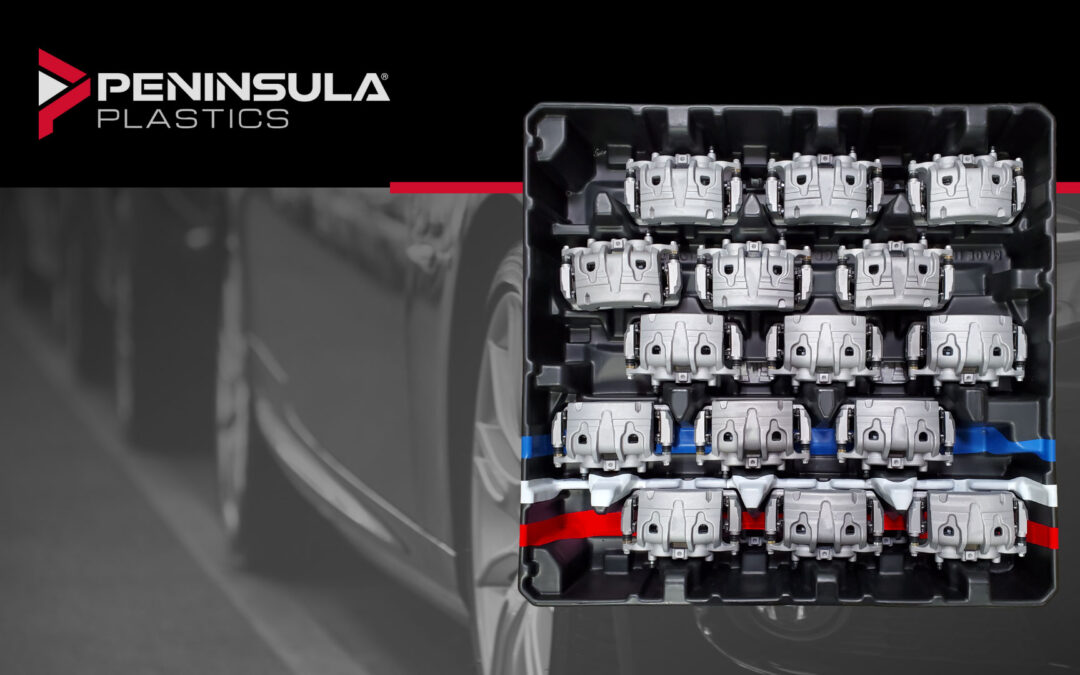

Separators

Separators play a crucial role in protecting textiles during shipping. They prevent compression and minimize the risk of damage. Separators nest each spool within the layers of the yarn pack and allow for variation in how many layers can be in each yarn pack. This customization can assist in ensuring space is being fully utilized during transportation.

Pallets / Base

The base supports all layers of the yarn pack. Peninsula Plastics produces both single sheet and twin sheet designs, with the twin sheet design being the most durable. Both designs can withstand substantial amounts of weight. Innovations in pallet design, such as anti-slip coatings and shock-absorbing materials, ensure that textile materials remain securely in place, even during turbulent transport.

Shipping Challenges and Solutions

Improper packaging and shipping of textiles can lead to a host of challenges that jeopardize the quality and marketability of the final products. For example:

Moisture Damage

Exposure to moisture can result in mold, mildew, and the deterioration of textile corrugated and wood packaging materials. At Peninsula Plastics, our packaging is produced from HDPE. HDPE is moisture-resistant, therefore mitigating the risk and greatly expanding the lifecycle of the textile industry’s packaging materials.

Rough Handling

Rough handling during loading, unloading, and transportation can cause fabric snagging, yarn breakage, or thread entanglement. Specialized lids, separators, and pallets minimize the impact of vibrations and shocks, ensuring the safe transit of textiles. Our units are incredibly durable and have a lifecycle that extends years further than corrugated yarn pallets transportation materials.

As the textile industry continues to grow, Peninsula Plastics continues to invest resources and technologies to help textile companies protect their fibers throughout the supply chain. For more information on our extensive textile solutions reach out to our sales team at sales@peninsulaplastics.com to learn more.