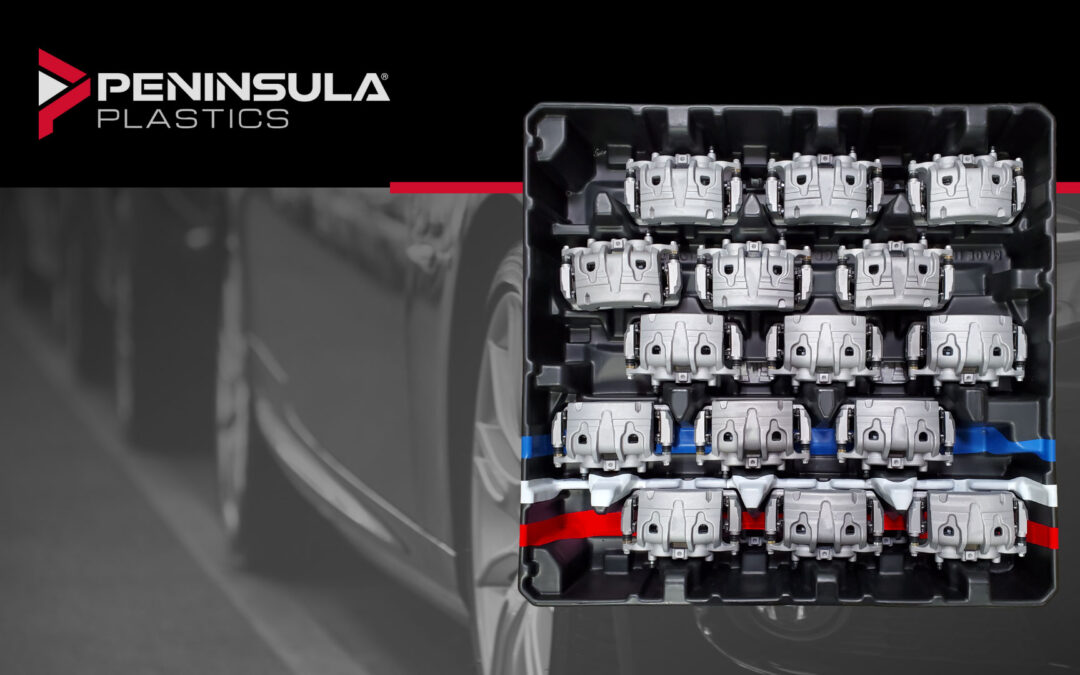

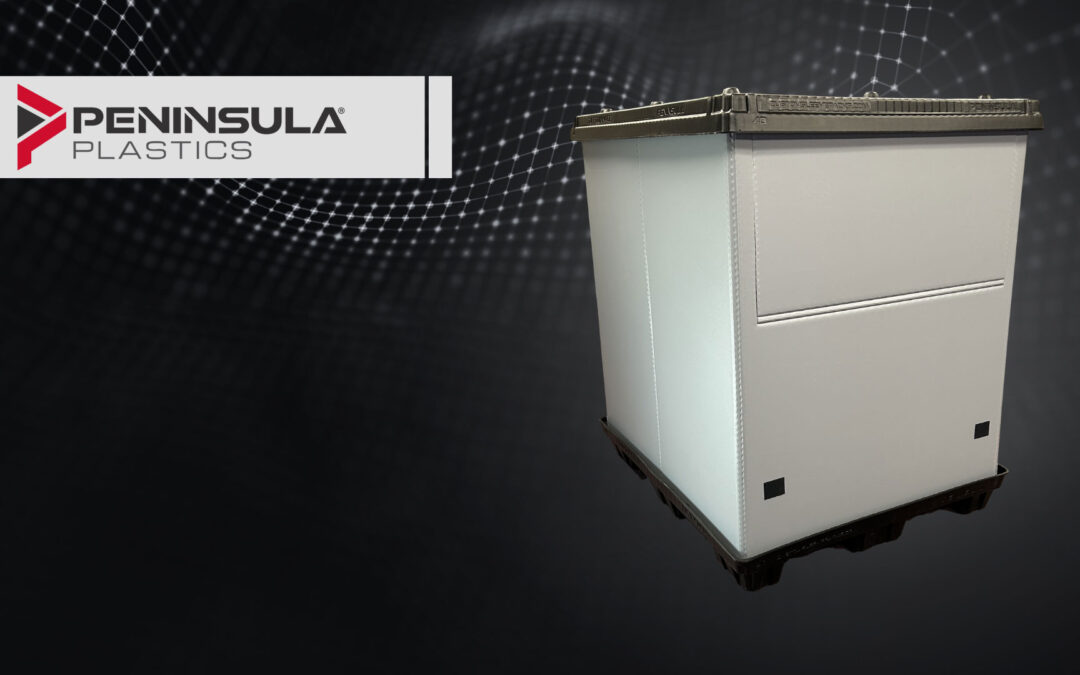

In the intricate world of material engineering, where durability meets sustainability, Peninsula Plastics has set a new standard in the returnable packaging industry with TUFF DUNNAGE®. As a leading innovator in thermoforming and injection molding, we understand the importance of product protection during warehousing and logistics operations. Our team of experts carefully selects material for trays, pallets, lids, and containers that enhance dunnage properties to support the longevity of your returnable packaging.

Materials Beyond the Basics

At the heart of TUFF DUNNAGE® lies a meticulous selection of materials. Peninsula Plastics embraces a diverse range of materials, including high-density polyethylene (HDPE) and acrylonitrile butadiene styrene (ABS) when thermoforming, and thermoplastic polyurethane (TPU), polypropylene (PP), and high-density polyethylene (HDPE) when injection molding. This versatility is not just a feature but a commitment to precision in meeting each product’s unique needs.

Unlike other solutions that may be bound by a singular material choice, Peninsula Plastics leverages the strengths of various materials to create unique packaging solutions that deliver optimal performance. This dynamic approach allows us to cater to a wide range of industries and applications. This supports tailored solutions for different products and their specific storage and transportation requirements.

Thermoforming & Injection Molding with High-Density Polyethylene (HDPE)

High-density polyethylene (HDPE), a key component in TUFF DUNNAGE® is known for its lightweight yet robust nature, adding another layer of resilience to TUFF DUNNAGE®. This material excels in providing strength without adding unnecessary weight, which creates a durable packaging solution. The lightweight nature of HDPE also contributes to the overall sustainability of our TUFF DUNNAGE®, as it minimizes the environmental impact associated with transportation.

Thermoforming with Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile butadiene styrene (ABS) is a versatile and widely used thermoplastic polymer known for its exceptional performance in a variety of applications. ABS is a copolymer of three main monomers: acrylonitrile, butadiene, and styrene. This unique combination gives ABS an impressive balance of strength, shock resistance, flatness, and stiffness. The material’s resistance to extreme temperatures, coupled with good dimensional stability and chemical resistance, makes it a suitable building material for many packaging applications.

Injection Molding with Thermoplastic Polyurethane (TPU)

Thermoplastic polyurethane (TPU) is known for its remarkable flexibility and resilience. This thermoplastic elastomer combines the best of rubber and plastic, offering a unique blend of durability and elasticity. The result is a material that can absorb shocks and impacts, providing an extra layer of protection for delicate and sensitive products.

Injection Molding with Polypropylene (PP)

Polypropylene (PP) contributes strength and stability to the overall structure. As a rugged and resistant thermoplastic, PP ensures that dunnage inserts maintain their shape and form even under challenging conditions. This is especially crucial in environments where external forces could compromise the integrity of the protective packaging.

Sustainable Engineering

Peninsula Plastics’ commitment to sustainability is embedded in the structure of TUFF DUNNAGE®. Peninsula Plastics recognizes the environmental impact of packaging materials, so we design our dunnage with a focus on sustainability. By incorporating recyclable materials, Peninsula Plastics takes pride in producing environmentally responsible packaging solutions.

In the world of material science and engineering, TUFF DUNNAGE® stands as a testament to innovation and precision. Peninsula Plastics’ unique approach to material selection ensures that every product receives adequate protection during storage and transportation. The result is a durable, sustainable, and versatile solution beyond packaging – it’s a commitment to the science of material excellence.