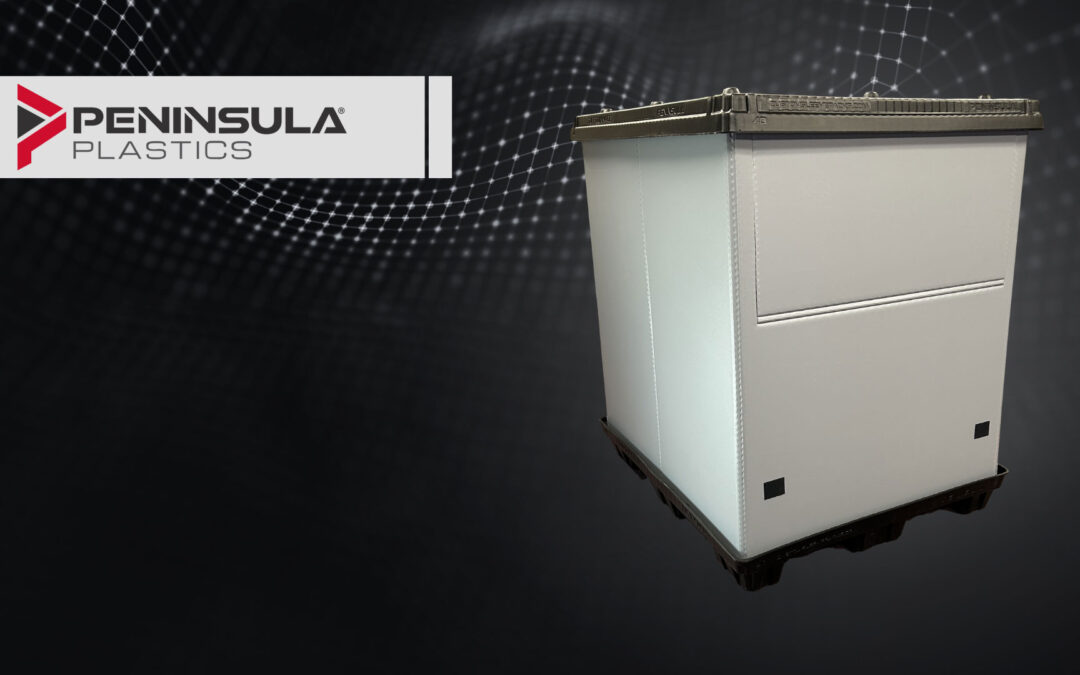

In the dynamic landscape of manufacturing and product packaging, the need for robust and versatile solutions is more critical than ever. Peninsula Plastics stands at the forefront of innovation by combining our thermoforming and injection molding capabilities to develop customized packaging solutions. Custom injection molding can be used in combination with thermoformed trays, pallets, and lids by using inserts designed to protect fragile and sensitive components.

The Power of TPU, PP and HDPE Inserts

Peninsula Plastics understands that when it comes to safeguarding sensitive surfaces, one size does not fit all. Our team of veteran manufacturing experts will analyze the product we are creating packaging for and determine the proper design and material type for the necessary insert. Thermoplastic polyurethane (TPU) is a material known for its exceptional resistance to abrasion, excellent flexibility, and remarkable shock absorption properties. Polypropylene (PP) and high density polyethylene (HDPE) are excellent material choices for products that demand an extra layer of durability and security. Whether you are packaging electronics, medical equipment, or automotive parts, injection molded inserts can offer the ideal balance of protection and support.

Diving into Custom Injection Molding

We are a leader in custom injection molding for thermoformed packaging, harnessing a wide range of materials to offer protection and support for your products. The injection molding process allows for precision and adaptability, making it suitable for numerous applications across diverse industries.

1. Various Materials

Peninsula Plastics is not bound by a singular material choice. In addition to thermoplastic polyurethane (TPU), polypropylene (PP), and high-density polyethylene (HDPE) Peninsula Plastics has the capability to use additional materials, ensuring that your product’s unique needs are met with precision. Our unique design and material selection make TUFF DUNNAGE® inserts the go-to solution for safeguarding delicate products.

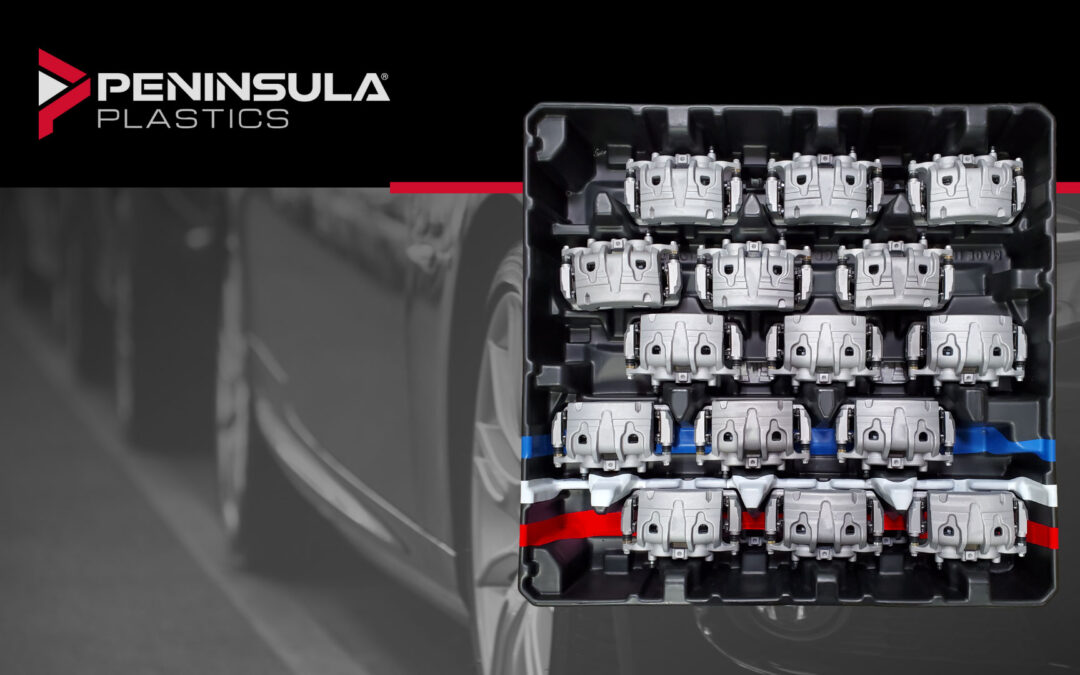

2. Unique Inserts for Fragile Components

Our team offers decades of experience in developing application specific injection molded inserts. Each unique insert is tailored to provide the perfect level of support and protection. Once installed in thermoformed trays, pallets or lids, they offer an added layer of safeguarding for fragile and sensitive components.

3. Custom Options

Peninsula Plastics goes the extra mile to ensure our solutions align perfectly with your requirements. We understand that each product and client is different, and we are ready to add a custom touch to your packaging solution.

Our expertise in working with materials like TPU, PP, and HDPE, coupled with our ability to create unique, custom-molded inserts, is a testament to our commitment to providing the best possible solutions. The trademarked TUFF DUNNAGE® inserts offer an unbeatable combination of support and protection. So, if you’re in need of a customized, top-tier solution for packaging your most delicate products, Peninsula Plastics is the partner you can trust to deliver unparalleled quality and reliability. Contact us today!