In the world of logistics, reliability and longevity for returnable packaging is vital. Innovative solutions are required that not only protect valuable commodities but also withstand the rigors of transportation and storage. Our thermoforming experts at Peninsula Plastics are committed to the development of sustainable pallets, both custom and standard, that are TUFF enough to withstand even the harshest of environments.

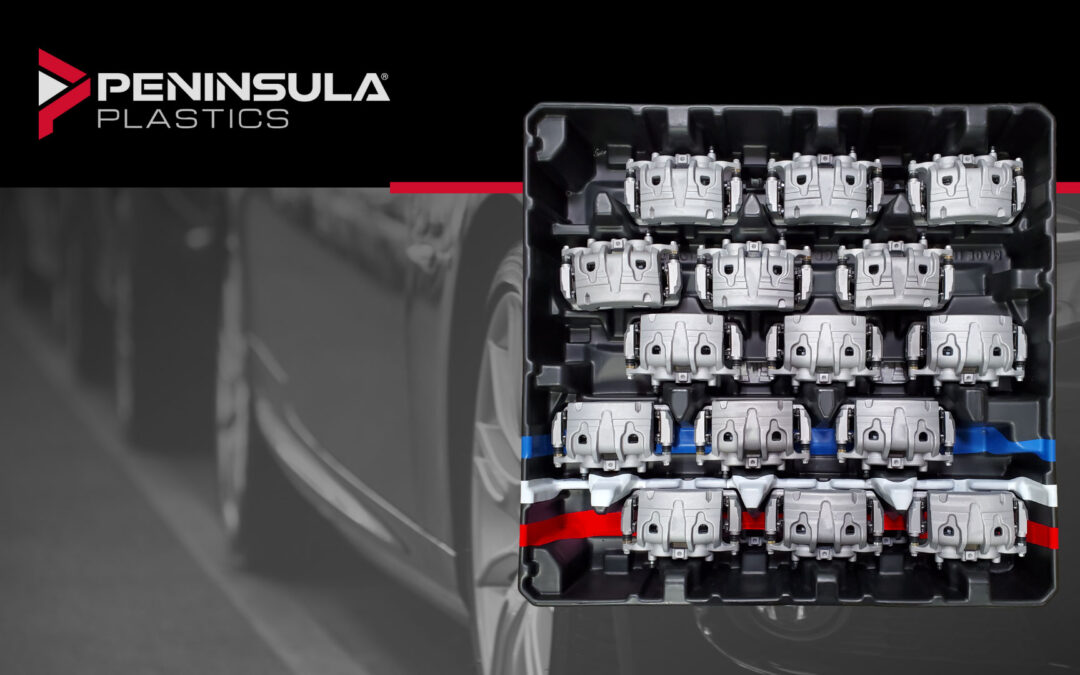

TUFF DUNNAGE®: Custom Pallets

Our TUFF DUNNAGE® can be tailored to meet specific requirements by providing in-house engineering and design services for custom pallet requests. Custom requests that we cater to include: light, medium, and heavy-duty pallets via our single-sheet and twin-sheet processes. Single-sheet pallets are formed from a tool using one extruded.

Sheet of material, whereas twin-sheet pallets are formed from two extruded sheets of material to support heavy-duty applications. Both single-sheet and twin-sheet pallets can be produced with custom features such as:

- Sleeve Tracks

- Belts

- Buckles

- Material Color

- UV Inhibitors

- 2” / 4” Orientation Stripes

- Personalized PSA Labels

- RFID Technology

- Mold-In Nomenclature / Logos

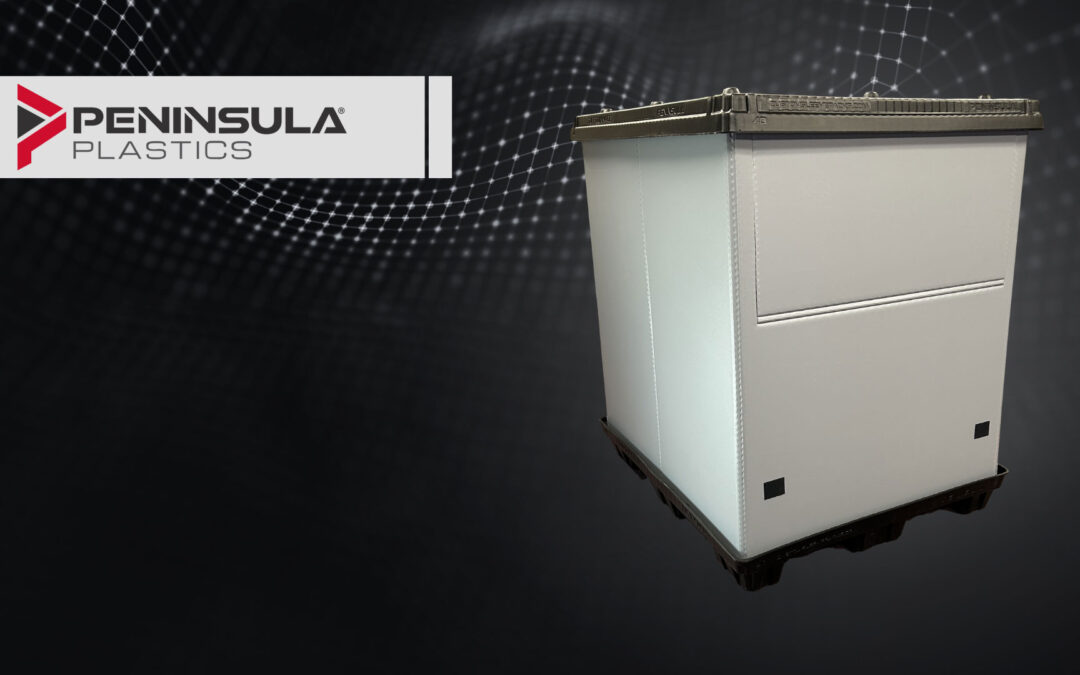

TUFF DUNNAGE®: Standard Pallets

With over 100 standard tools readily available, our standard pallet collection offers optimal safeguarding for your products, while reducing expenses and expediting your timeline. Standard pallets are offered in a variety of sizes and styles with a handful of customizable options available. Pallet types include mirror-image pallets, flat-bottom pallets, single-sheet pallets, and twin-sheet pallets.

Why TUFF DUNNAGE®?

TUFF DUNNAGE® pallets are not just a product – they are a benchmark of excellence. Here at Peninsula Plastics, our mission is to provide you with the most resilient returnable packaging solutions. Upgrade to TUFF DUNNAGE® and experience the difference in reliability and longevity for your packaging needs.